Let’s say for A or B reason an aircraft got scratched.

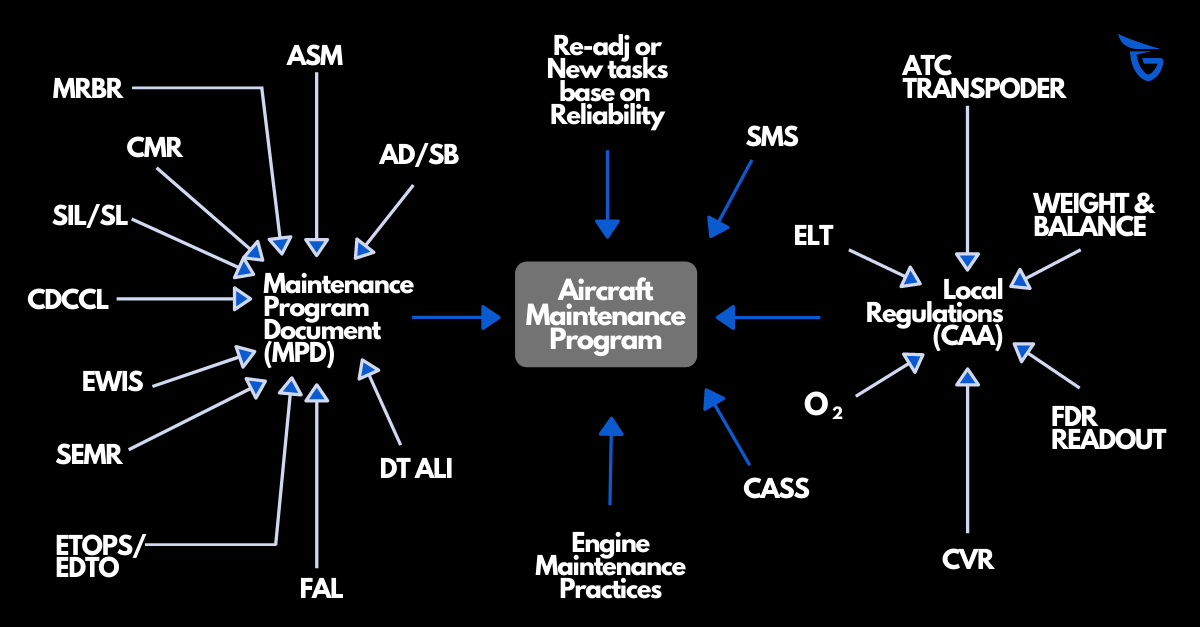

The licensed engineer (EASA) or A&P mechanic (FAA) will be in charge of inspecting the area/surface, evaluating it for damage specifications, its relation to main structures like frames, stringers, and depending on the results, instructions are to be performed. These instructions are generated based on the rules written in the manufacturer’s manuals. There can be 3 types of actions:

1. Leave as it is. When the damage does not have any relevant influence on the aircraft’s safety that would require any type of repair, remember that the aircraft skin allowances are counted in parts of a millimeter. The damage can be left as is, but later an inspection and possible further limitations might have to take place.

2. Perform Repair. When the results of the inspection require such actions as filler repairs, patch repairs, skin replacements, doubler repairs, tripler repairs, etc, it is mandatory to perform them before the next flight.

3. No immediate design is available for repair. Commonly, the manufacturer has written in its manuals the step by step instructions to evaluate the damage that leads you to the decision of contacting the manufacturer. In this case, the manufacturer does a case-study of the damage in order to provide detailed guidelines to perform the repair.

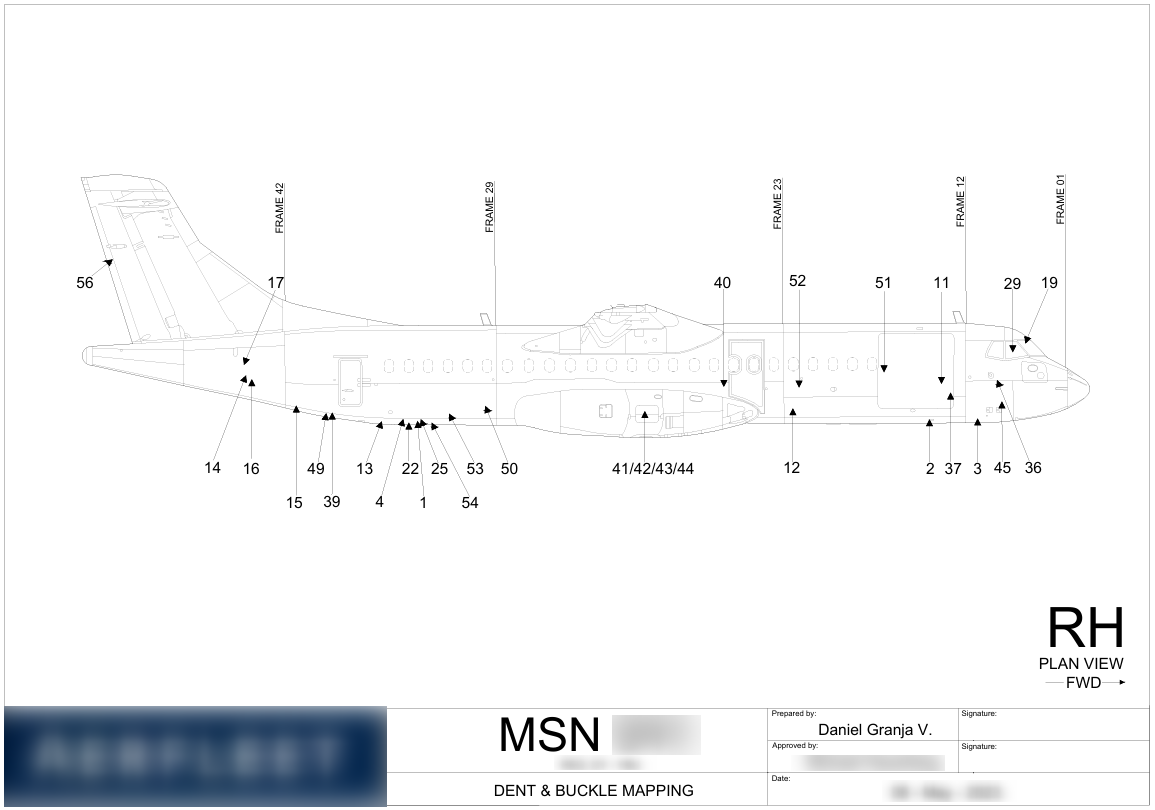

No matter what of the mentioned actions are applied, the damage or repair should be mapped; therefore, the word “mapping”.

Mapping is the term used to document the location of the damage or repair in a visual form. This is just the tip of the iceberg, but it is crucial for tracking important changes and repairs that require periodical inspections, etc.

There are different ways to map a damage/repair, the one we use and recommend is as follows:

ATA + Seq Number:

In case a damage is internal, for instance, corrosion, the manufacturer’s instructions can involve slice repairs, modifications, etc of the aircraft’s main structures like floor beams, frames, stringers, floor panels. Make sure that the internal damages are mentioned in the Dent & buckle list and check if there is any interval of inspection for that zone “post repair”. Following that, register it.

A controlled repair commonly comes after the repair instructions provided like in case 3, or when flight limitations exist before next repair event, like inspections related to flight cycles (structures stress related). This is done to make sure that there are no signs of propagation of any type of damage at or near the zone.

In today’s world, the science and studies; all the results of investments in innovation and development inside the aircraft manufacturing industry allow us to see the birth of aircraft built with more composite material structures.

Nowadays we can find aircraft models with entire fuselages sections made of weaved threads of carbon fiber. The whole floor is made of honeycomb, kevlar and carbon fiber combined with cured fillers and sealants on all modern commercial aircraft. Why? Because composite material is stronger than other materials and lighter than most structures, these properties help the designers to decide which material to use while designing the aircraft’s structures.

If a damage is external, it must be registered inside of the mapping of the aircraft, no matter which type of material it is.

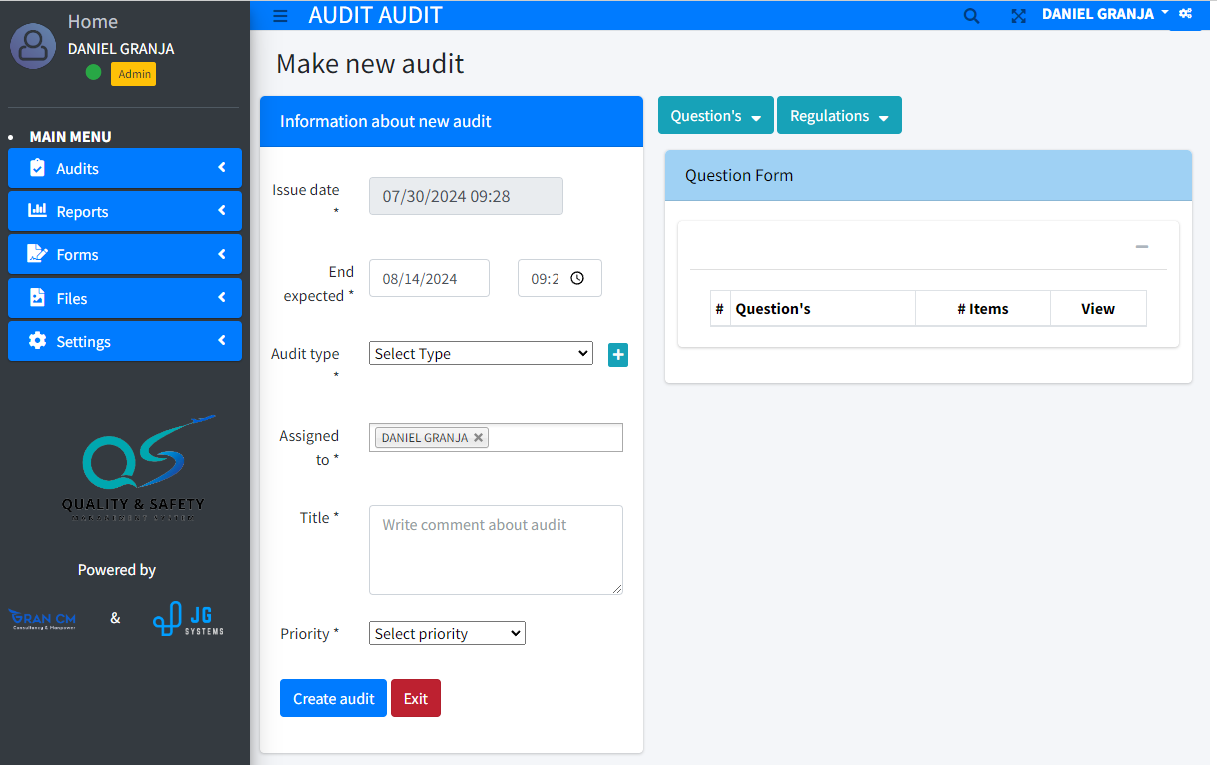

In case you or your organization owns an aircraft, and it needs a mapping review, don’t hesitate to contact us.

Remember, consult with experts.