Line Planning in aircraft maintenance means “to plan” maintenance tasks for one or several aircraft during the periods of time that the aircraft is scheduled to remain on ground in the middle of its regular operations.

It is also called Line Maintenance Planning Engineering, since planning is not as easy as it sounds. Let’s get into a regular day of an Airline Line Planning Engineer following a usual case:

The CAMO (EASA) or planning department (FAA) provides a list of jobs to be accomplished during aircraft stops between flights. The latter means that besides the responsibilities of planning an aircraft maintenance task it is vital to take into account:

1. Flight Schedule

It is impossible to accomplish the job without the plane, so working closely and regularly with the aircraft flight schedule is a big must. It had happen very often that for A or B reason an aircraft had a delay in it’s previous flight causing it’s arrival time to shift, this way reducing availability to work on it during it’s time on ground or in case of arriving earlier there is a chance to accomplish something extra.

2. Engineering

Considering the independent facts that are not controlled by the normal routine of planning an aircraft maintenance task logic becomes the best friend of engineering.

A Planner’s responsibility in terms of aircraft parts is to be aware of their availability consumables linked to its installation and how the system works in case the workflow stops.

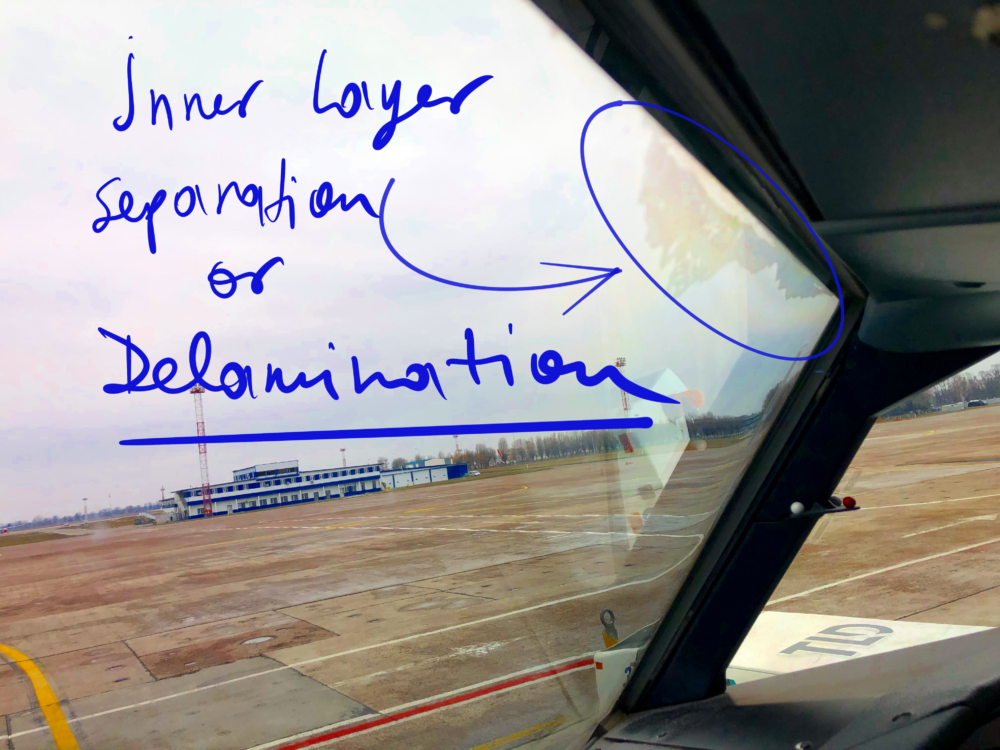

Besides this, a sudden defect can arise during a routine check, demanding a part change, job that can be scheduled for next stop, however, it might be needed to analyze if the replacing part matches the aircraft’s requirements: a panel replacement, for example.

Even though aircraft look the same, not all the parts are the same in all aircraft. The engineer in charge must check part’s applicability and or effectivity through the aircraft’s manufacturer codes in parallel with the instructions provided by the aircraft manufacturer’s manuals, next he or she should check replacement instructions in case any special requirement(3.) has to be considered.

Note: Depending on the modifications or de-modifications done during aircraft manufacture in seek of having a better and safer aircraft, parts can differ by minor changes and this is noted through the component’s part number (PN). In case of systems parts, the upgrades are usually issued by each separate manufacturer.

2.1 Special Requirements

There are several requirements to have in mind while planning for Line Maintenance.

• Airport rules

For example, in almost all airports there are sound restrictions, meaning that for engine run tests the aircraft has to be relocated to a remote place, this takes time and a small crew to control and perform engine runs.

It is easy to think it takes no time to replace a valve, but all the prep, tests and paperwork recording consume more time than replacing the valve itself. Taking airport rules into consideration while planning is another must.

• Tools & Parts

Certain tasks require non standard tools, in cases parts and consumables that are not in the basic minimum workshop inventory, it is important to have a look for special tools or part requirements when planning each maintenance task

• Certified Staff

An aircraft B1 (EASA) or A&P (FAA) cannot do NDT jobs without being NDT certified, or as in Europe a B1 engineer certified on an Airbus 320 aircraft cannot sign off jobs done on a Boeing 777 aircraft, or do B2/(avionics) jobs either. This is also mandatory to consider when carrying out Maintenance Planning Engineering, always consult with the maintenance manager in charge of the station for staff availability.

• Troubleshooting

In case the aircraft arrives with an unknown failure that has no fix other than to communicate with the manufacturer for further troubleshooting instructions, the planner engineer will trigger and handle the request all the way until the defect is rectified and all relevant parties are notified.

2.2 Equipment vs jobs

In order to maximize efficiency, it is important to group all tasks that have related zones or step requirements when using the help of special equipment such as borescopes, man lifts, pitot testers, etc. without disregarding the time the aircraft will be available.

3. Climate

Believe it or not, this truly is an influencing factor when there is no hangar availability, inspections can be simply delayed due to heavy rain, fog, hailstorms, rapid winds, etc. It is also important to be aware of the climate conditions vs. the job requirements, specially when the job is to be performed outside of the airplane.

Remember to follow the aircraft’s manufacturer instructions and your local airworthiness authority rules all the time.

4. Communications & Digital Tools

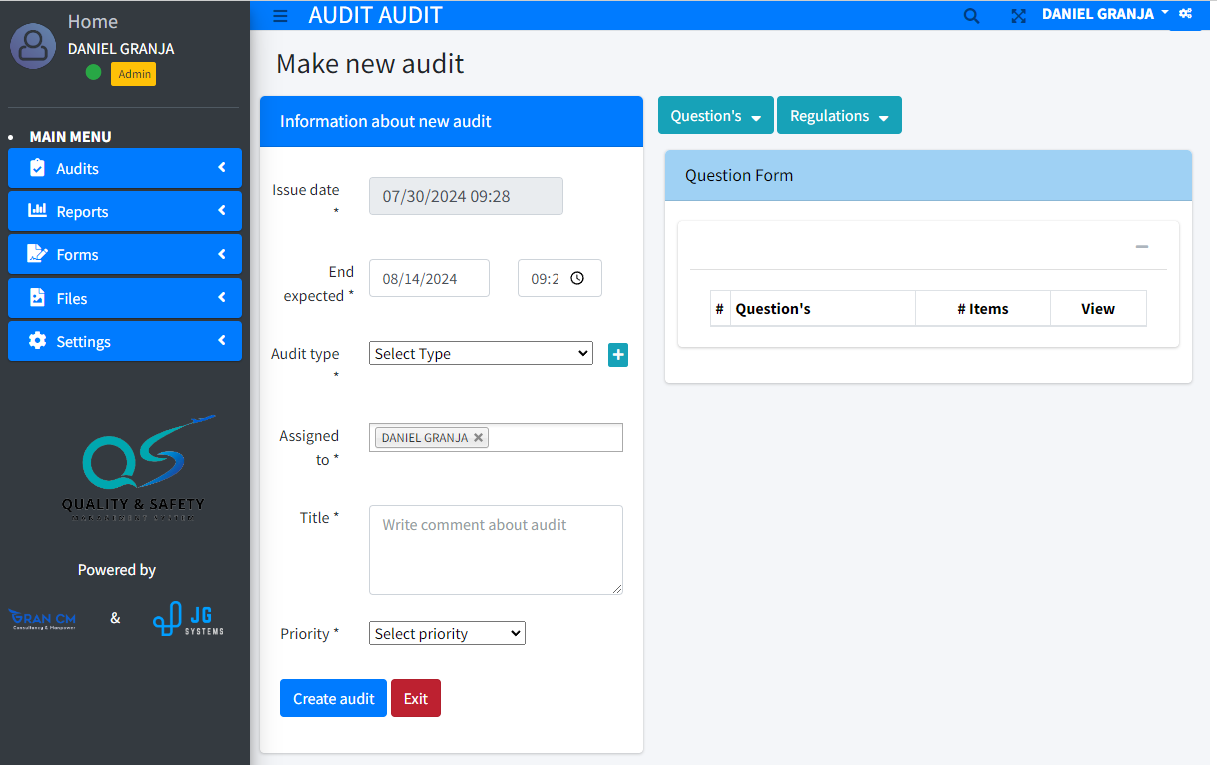

Taking care of the above points and ensuring clear professional communication is crucial since the job performance involves several people in charge. Communication can be a challenge sometimes, and in Line Maintenance, the Line Planner is the channel of communication between CAMO (Planning) and Part 145 (MRO). The use of digital tools in today’s work is necessary to minimize human error, therefore, it is always recommendable to use an automated system to control the compliance of each maintenance task.

Correct communication brings faster answers, therefore, it is a must for a Line Planner to be a good communicator to be able to take correct decisions.

Line Mx

GranCM offers line planning engineering services on Line Mx platform. The latter is a user friendly line maintenance control and management system. For more info see the video below or visit www.grancm.tech.

Subscribe:

Attention aviation enthusiasts! Soar to new heights with our blog, where we share the latest updates, insights, and stories from the fascinating world of aviation. By subscribing to our notifications, you’ll never miss a post—whether it’s breaking news, detailed analyses of cutting-edge aircraft, or captivating tales from the skies. Join our community of passionate aviators and stay informed, inspired, and engaged with the ever-evolving wonders of flight. Subscribe now and keep your love for aviation flying high!