Airworthiness

What does Wikipedia say?

“Airworthiness is the measure of an aircraft’s suitability for safe flight. Certification of airworthiness is conferred by a certificate of airworthiness from the state of aircraft registry national aviation authority, and is maintained by performing the required maintenance actions.”

In practice, airworthiness is all about a minimum required condition that an asset (aircraft, helicopter) must meet to keep airworthy. The condition usually covers 2 main aspects of the asset:

1. Physical

The eye is the first “tool” used when checking an aircraft’s condition. All aircraft go under multiple inspections tens of thousands of times a year.

When a consultant does a physical inspection, he usually starts from looking at general external and cabin conditions to inspecting each component’s placards, exterior repairs, dents, etc.

The specialist performing a physical inspection must have the required knowledge and experience on the aircraft type and model at hand.

Usually, if timeframes are short for an inspection, lack of knowledge about the asset model’s strengths & weaknesses can result in gathering inconsistent information. Thus, only experienced inspectors can do an inspection accurately and efficiently, providing correct conclusions on the aircraft physical state to the client.

One of GranCM’s consultant recent challenges during the inspection was to inspect 4 aircraft within 8 hours without missing every single item from a checklist that contained 200 items. It is more than obvious that an engineer with good theoretical knowledge but limited practical experience on a required aircraft is less likely to complete such a task in a quality manner but it is absolutely a normal thing to do for an engineer with hands-on experience on this particular aircraft type. Thanks to the careful selection of the consultant’s profile and expertise of GranCM’s assigned engineer, the inspection was successfully completed.

Getting back to the routine steps of physical inspection, it should be mentioned that aircraft maintenance tasks are executed daily, and the signature of the certified mechanic, engineer, or inspector is what assures that a maintenance step has been accomplished or that an aircraft is in condition for release to service.

2. Technical documentation

Technical documentation review is equally important during aircraft inspections, technical documents are proof of maintenance inputs, changes, contain important information about the asset such as weight variant, components installed, etc. The set of documents to be reviewed are not only related to aircraft operations, but also related to the manufacturer, operator’s or CAMO record-keeping and airworthiness authorities from where the aircraft came registered at “birth” and where it is currently registered, documents like life limitation sheets, weight and balance reports, airworthiness directives compliance, etc.

These can represent thousands of papers tied to each asset, thousands of papers with technical specifications, log books that track daily issues, from how many quarts of oil were poured into which particular engine oil tank to the email from the manufacturer giving instructions for damage mapping.

Consultants that perform paperwork inspection are also able to support the client remotely since their physical presence isn’t required for this job. Only access to the documents is required, which in digital epoch is shared within several clicks from any place of the world. Of course, there are still exceptional cases when technical records are held in an “old school” and “affordable” way (nothing scanned, no digital tracking), then the inspection can be done only onsite.

Compliance Control

Now that we know a little more in general about airworthiness, let’s talk about compliance control.

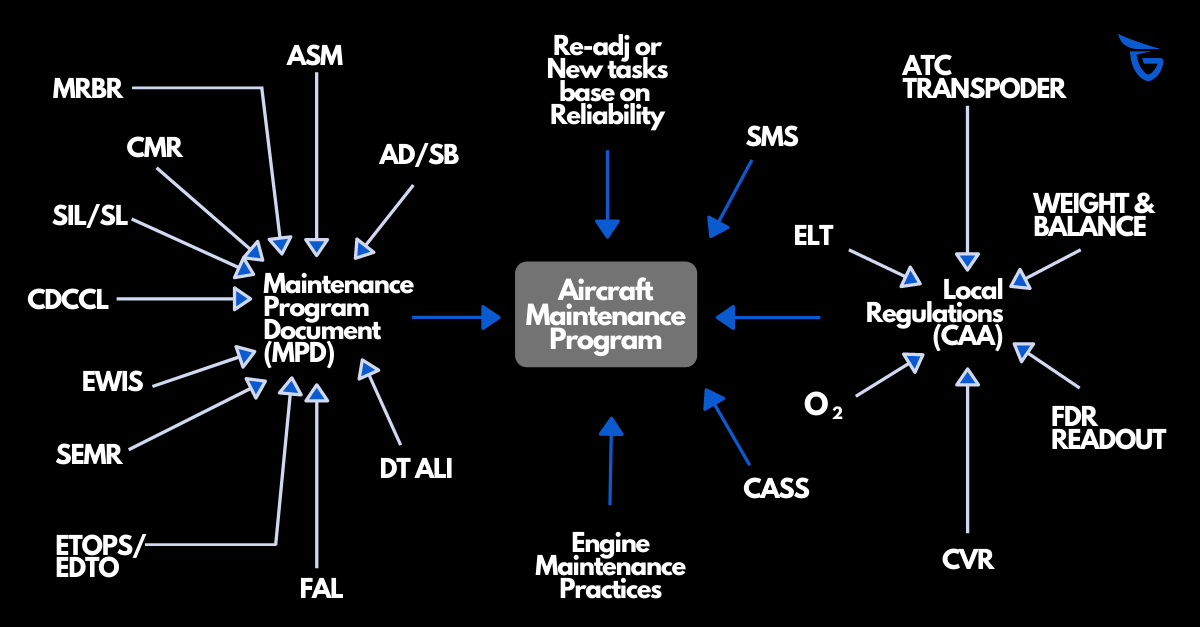

Compliance control presupposes having track of all items related to airworthiness. Besides permits and manuals, there are maintenance time-controlled items (such as flight hours, flight cycles, calendar date). It involves auditing aircraft maintenance technical documentation regularly in order to assure correct control, control of maintenance documentation related to compliance with the approved aircraft maintenance program that the operator holds for the specific aircraft, the manufacturer stated life limitations and conditions, defect rectification reports, etc.

How was airworthiness planning/CAMO control in the old days?.

Once I asked a retired colleague who was the first ATR engineer in Denmark:

– How was it when you had to control airworthiness in the old days?

He answered

- Every morning we opened our metal drawer cabinet and counted each maintenance task card one by one, and that was the tracking method.

- Airworthiness directives were received through fax.

Things have changed since then. The internet is now the fastest source and channel of information which has changed the way CAMO is performed. Besides, airworthiness related items, other maintenance items and due-control (LDND) are now also controlled under tracking systems; maintenance data is entered manually and controlled through digital platforms or so-called ERPs. These tools help to keep track of tasks due dates, starting from a functional task to the life limit of an engine HPT blade.

Possibility to organize documentation in digital folders and put them in a cloud storage is a huge advantage in comparison with how things were handled in the past. Once I audited an aircraft that operated in China in the 80s, all the log books from that operator were manually sewed one by one; and to my surprise they were incredibly organized. I bet at the time that method was ideal, for now the problem in that case is the language: lack of documentation in English must have been a headache for the CAMO in charge of that asset.

Nowadays, many tasks are controlled through Excel, this program can become indispensable for diverse tasks; for example, an inspection that contemplates many items and doesn’t require complex tracking methods, each item is easily controlled in a row with columns. For more sophisticated jobs, complex pivot tables, pie chart and overviews can be built with help of digital tools such as Powee BI or specific software.

Software

How has software influenced airworthiness control in regards to record keeping and task accomplishment control?

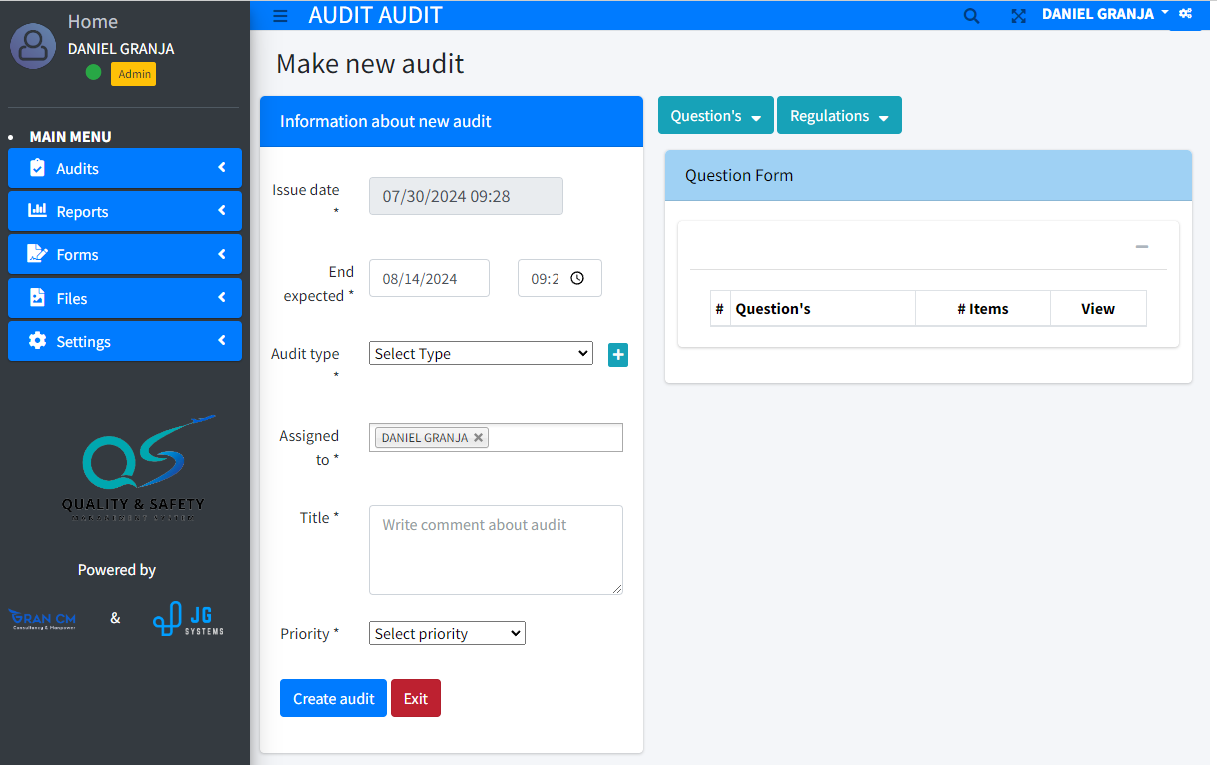

The appearance of digital tools in the planning and maintenance areas of the industry has been a contributing factor for increasing safety and efficiency. The control is no longer made manually: you can have a status, a forecast and a history of records within a couple clicks. Nowadays, we are even able to access any document from any smart device be it a tablet or a phone.

Let’s take a real life example showing when a digital tool comes in handy.

A new customer always means a new way of handling information, luckily information is just data organized in a certain way. We are able to take the customer’s inspection report meant for the project, re-organize, parametrize and use our customized spreadsheet to keep track of the asset in an easy way that allows live updates.

Now we are able to add links to reports and redirect users to specific information, leave notes, comments, answers. We can be creative once we have the information uploaded, and we can analyze it afterward.

I assume in the old days after receiving the report through fax (when the request was from abroad), the engineer had to make multiple notes and record data by hand hoping not to miss any item; he also went through the inspection, prepared the report and sent it back through fax several days if not weeks later, not mentioning that it was not that easy to take pictures in the old days as of now that you can do a photo report, or damage evaluation with the camera inside a smartphone.

In GranCM we are not only aware of modern digital tools employed in the industry and how to use them, but we also develop our own, always looking for new ones as our service always presupposes job done with a responsible and organized record keeping. That is why we also try to look further and create tools such as Consultant and Line Mx to make our cooperation with clients transparent, easy, and extremely professional. It’s a win-win!

Remember, consult with experts!