Most of us have seen what a window of an airplane looks like, and at first thought, it may seem like an ordinary window, but in fact, it is the result of engineering joint ventures between aerodynamics, the strength of materials, thermodynamics, and heat transfer science.

At the beginning of commercial air travel, aircraft passenger windows had a square shape like those in Havilland DH.106 Comet aircraft. Later, it was proved that a square shape aircraft passenger cabin window is vulnerable to stress and cracks. In 1953, three planes fell apart in the air, killing 56 people in total. The tragedy propelled the new design of a stronger and more resistant type of window of the circular shape that we see today.

Nowadays, we fly modern passenger aircraft with electro-chromatic dimmable windows, for example, the B787 Dreamliner. With the click of a button, the passenger can dim the entire window. Windshields are even more complicated, they contain sensors and anti-ice systems to avoid ice formation which can pose a serious threat to flight safety.

Purpose:

The obvious reason why the windows exist in an aircraft is to be able to observe through the “glass”. In case of cargo or freighter aircraft, cabin windows are not necessary because there are no passengers inside and nobody to observe the surrounding. Modern freighters can count with cameras installed in the exterior of the aircraft to help them have the 380 visibility or the MOD can be embodied; for more information, consult with the aircraft manufacturer.

Inspection:

To inspect any window, it is necessary to know what type of damages may be found and what they look like.

Chips and nicks are damages usually caused by having external objects (FOD) impact the surface of the acrylic pane or glass.

Chips are also classified into “Peel chips (interlayer chip)”, and “External chip (Outer surface chip)” like shell type and V shaped chips.

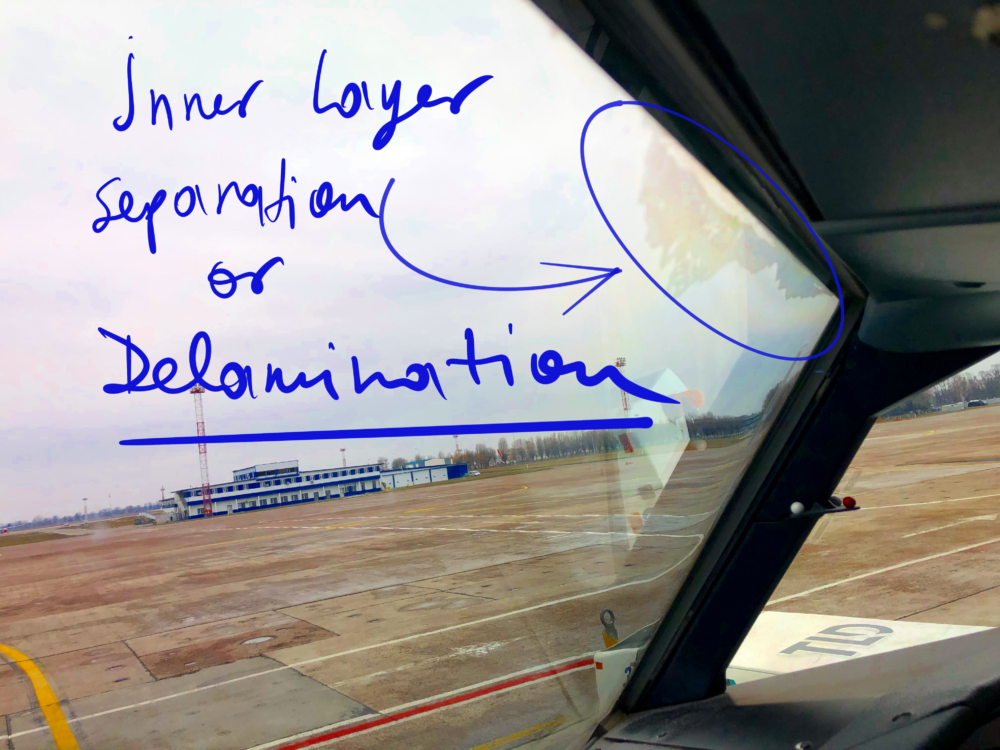

Delamination damage presupposes the separation of the window from inner layers; delamination blurs visibility and the expansion of this damage must be controlled until a windshield/window is replaced.

Haze may appear due to the lack of coverage of the heating system in some area of the windshield and it looks like a light blue cloudiness between inner layers.

Bubbles can be found within layers as a result of a damaged window heat control system. It is usual to find a small group of bubbles or brown dark bubbles.

Scratches are the displacement of material in a linear trajectory from the surface of the pane or glass.

Fogging counts for water condensation and subsequent visible moisture. It can be caused either by excessive humidity or a leak through the window seal.

Warping or deformation is a visible deformation from the window’s original shape and can be the result of a long-term exposure to moisture and high temperatures.

Cracks occur within the interlayers around the outboard edge of the windshield and at bolt holes.

For more details about inspection performance, consult within your aircraft manufacturer manual and/or local Civil Airworthiness Authorities if necessary.

If you are looking for consultancy, feel free to navigate through our services and prices on this website, once you are convinced feel free to submit your project request form in order to receive a free of charge quote to cover your project.

Remember, consult with experts.

Subscribe:

Attention aviation enthusiasts! Soar to new heights with our blog, where we share the latest updates, insights, and stories from the fascinating world of aviation. By subscribing to our notifications, you’ll never miss a post—whether it’s breaking news, detailed analyses of cutting-edge aircraft, or captivating tales from the skies. Join our community of passionate aviators and stay informed, inspired, and engaged with the ever-evolving wonders of flight. Subscribe now and keep your love for aviation flying high!